Unveiling the Power of RainierGPR Concrete Scanning Technology

Unveiling the Power of RainierGPR Concrete Scanning Technology

Blog Article

Harness the Strategic Edge of Concrete Scanning for Unparalleled Task Success and Quality Control

In the world of contemporary construction and facilities advancement, the usage of concrete scanning modern technology has arised as a critical tool for ensuring project success and maintaining high quality requirements. The real power of concrete scanning exists not just in its ability to enhance project results yet additionally in its ability to revolutionize conventional methods, setting a new benchmark for precision and efficiency in the building market.

The Value of Concrete Scanning

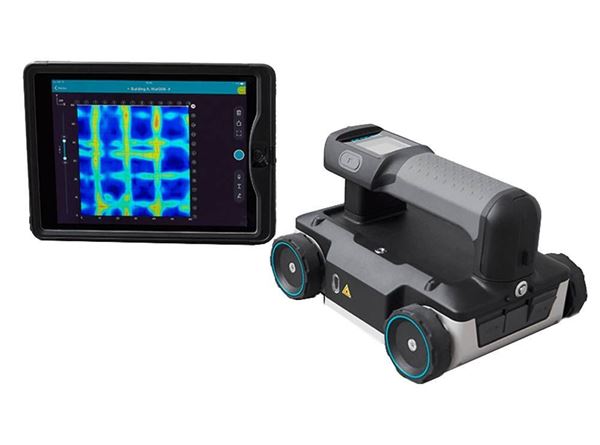

Concrete scanning is an essential action in building and construction projects to ensure the safety and integrity of frameworks. By making use of numerous scanning technologies such as Ground Permeating Radar (GPR) and electro-magnetic induction, construction teams can non-destructively assess the subsurface of concrete frameworks to determine possible dangers like rebar, channels, or post-tension cables. This information is crucial for job supervisors, service providers, and designers to make educated decisions and stay clear of expensive mistakes throughout the building process.

One of the key factors why concrete scanning is so crucial is its ability to stop mishaps and injuries on the construction website. Mistakenly cutting via an online electrical conduit or damaging post-tension wires can have tragic repercussions, not just in terms of safety and security however additionally in terms of task delays and monetary effects. By carrying out comprehensive concrete scanning prior to any boring, reducing, or coring activities, building and construction groups can reduce threats and produce a more secure working environment for everybody involved.

In enhancement to security considerations, concrete scanning likewise plays a vital role in making sure the long-term toughness and top quality of the structure. By identifying any type of problems or abnormalities concealed under the surface, such as spaces or delamination, very early treatment can be executed to resolve these concerns before they intensify right into even more substantial problems. Eventually, spending in concrete scanning is a proactive procedure that can conserve time, money, and resources in the future, while also promoting the highest requirements of building and construction quality.

Advanced Modern Technology for Accurate Outcomes

By integrating these sophisticated innovations right into concrete scanning methods, building teams can improve workflows, decrease task delays, and make certain the overall top quality and success of the task. The accuracy and performance provided by these devices contribute considerably to the project's success by facilitating notified decision-making and improving top quality guarantee procedures.

Enhancing Project Performance and Timelines

In addition, concrete scanning makes it possible for teams to recognize prospective hazards and structural weak points at an early stage, enabling timely remediation and protecting against crashes that can derail job timelines. The real-time data supplied by scanning devices assists in educated decision-making, bring about smoother control among different trades and stakeholders. This boosted partnership decreases conflicts, improves performance, and ultimately speeds up project shipment.

Additionally, by proactively addressing concerns via concrete scanning, construction groups can abide by schedules better, reduce downtime, and maximize resource allocation. The ability to spot covert challenges and validate structural stability efficiently contributes to overall job performance and timelines, making certain effective results and client contentment.

Ensuring Safety And Security and Danger Reduction

Threat reduction approaches can be improved with the comprehensive information given by concrete scanning, allowing project teams to make educated choices that decrease the probability of unanticipated events. In addition, by precisely drawing up subsurface problems, contractors can stay clear of expensive rework, delays, and damages to existing frameworks, additionally adding to total task safety and success. Executing concrete scanning as a routine method not only ensures a much safer job environment however additionally imparts self-confidence in stakeholders regarding the job's dedication to top quality and threat monitoring.

Quality Guarantee With Concrete Scanning

Concrete scanning plays a critical duty in upholding high quality guarantee standards within building projects. By utilizing sophisticated scanning modern technologies such as Ground Permeating Radar (GPR) and Concrete X-ray, task supervisors and engineers can ensure the stability and quality of concrete structures. Via concrete scanning, prospective issues, such as spaces, fractures, or strengthening bar blockage, can be spotted non-destructively, permitting for prompt interventions to maintain the structural integrity of the task.

Quality guarantee through concrete scanning not just assists in identifying existing problems but also allows proactive procedures to protect against future problems that could endanger the safety and security and longevity of the framework. By conducting complete scans at key stages of building and construction, groups can validate the precision of structural strategies, confirm the positioning of vital elements, and attend to any kind of deviations immediately. This proactive strategy decreases rework, decreases pricey hold-ups, and ultimately leads to the shipment of high-grade, sturdy structures that meet or go beyond market requirements.

Conclusion

Finally, concrete scanning plays a critical role in making sure job success, top quality, safety and security, and efficiency guarantee. By making use of sophisticated technology for specific outcomes, building and construction jobs can be finished with higher accuracy and within timelines. The tactical edge given by concrete scanning enables proactive danger reduction and improves general job administration. Integrating concrete scanning right into building processes is crucial for attaining unparalleled success and guaranteeing quality outcomes - RainierGPR Concrete Scanning.

In the world of modern-day building and infrastructure growth, the use of concrete scanning modern technology has arised as a pivotal device for making sure task success and maintaining high quality requirements. By integrating these innovative modern technologies into concrete More about the author scanning methods, building and construction groups can enhance operations, decrease job hold-ups, and make sure the total top quality and success of the task.Given the you can try these out essential nature of project performance and timelines in building and construction monitoring, the emphasis currently changes towards ensuring safety and security and mitigating dangers within the task environment.Concrete scanning plays a critical function in maintaining quality guarantee criteria within construction projects. By using innovative scanning technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, job supervisors and engineers can ensure the integrity and high quality of concrete structures.

Report this page